China’s Food-Grade Bottle-to-Bottle Recycling Faces Policy Breakthrough? Polytech Positions Itself Ahead of the Curve

Publication Date:2025-08-20

In recent years, plastic pollution control and circular economy development have been increasingly incorporated into China’s national strategic agenda, and the use of food-grade recycled plastics has gradually gained policy attention. For the bottle-to-bottle (B2B) recycling model, this may represent a significant ‘policy breakthrough.

一、Policy Context: The ‘Gate’ for Food-Grade Recycled Plastics in China

By the end of 2024, China’s State Administration for Market Regulation (SAMR), along with several other ministries, issued multiple policy documents related to recycled plastics. These initiatives aim to raise standards for the collection and utilization of waste products and to improve the quality and application standards of recycled materials.

Compared with the mature frameworks of Europe, the U.S., and Japan, China’s food-grade recycled PET (rPET) market remains in a cautious development phase. Current regulatory priorities include traceability management, quality control, and safety assessments. Once restrictions are fully lifted, the bottle-to-bottle recycling model is expected to unleash enormous domestic market potential.

1.Current Regulatory Framework

China’s regulation of food-contact materials is primarily based on the Food Safety Law and the General Safety Requirements for Food Contact Materials and Articles (GB 4806.1-2016). At present, the use of recycled plastics in food-contact applications remains tightly restricted, allowing only virgin resins or recycled materials that meet specific requirements.

2.Signals of Policy Easing

On August 1, 2025, the State Administration for Market Regulation (SAMR) and the Standardization Administration of China (SAC) simultaneously released nine new national standards for recycled plastics, which will take effect on February 1, 2026. These standards cover quality benchmarks, product evaluation, material identification, recyclability and eco-design principles, traceability, and environmental impact assessments. Collectively, they lay the technical foundation for a closed-loop recycling system and the advancement of food-grade applications.

二、China’s Bottle-to-Bottle Recycling: Global Trends and Domestic Landscape

Bottle-to-bottle recycling involves collecting, washing, and re-pelletizing discarded PET bottles, followed by advanced purification processes such as solid-state polymerization (SSP), to produce beverage bottles that are safe for direct food contact.

Global Trends:In Europe and the United States, beverage bottles are now widely required to contain a certain proportion of recycled PET (rPET). For example, EU regulations mandate that by 2030, beverage bottles must include at least 30% recycled PET content.

Domestic Landscape:In China, beverage bottle production still relies primarily on virgin PET, with rPET largely used in non-food-grade applications such as fibers and PET sheets. However, under the dual pressures of carbon neutrality goals (‘dual carbon’ policy) and the circular economy agenda, beverage brands are showing rapidly growing interest in food-grade rPET.

三、Opportunities in China: Policy and Market Dual-Engine Growth

Once policies are relaxed, China’s bottle-to-bottle recycling industry is expected to experience rapid growth.”

The High-Value Proposition of Bottle-to-Bottle Closed-Loop Recycling:

In China, millions of tons of post-consumer PET bottles generated annually are still predominantly directed toward downcycling applications such as polyester fiber production. Bottle-to-bottle recycling, by contrast, enables high-value circular utilization of raw materials, creating stronger economic incentives for collection and processing.

This shift in application from downcycled products to bottle-grade materials will not only drive PET bottle resources to be concentrated in food-grade packaging but also push the fiber industry to accelerate the development of its own fiber-to-fiber recycling systems. Ultimately, this will create a structural competition in the PET feedstock market between high-value bottle-grade recycling and fiber reuse demand.

Environmental and Cost Advantages::

Food-grade rPET can reduce carbon emissions by over 50% compared to virgin PET, while maintaining cost competitiveness during periods of crude oil price volatility.

四、Polytech’s Early Deployment: Full-Process Capability from Washing to SSP

As an environmental engineering company deeply engaged in recycled PET resource recovery and technology integration, Polytech holds a significant competitive edge in bottle-to-bottle recycling processes.

On February 17, 2023, Polytech received a No Objection Letter (NOL) from the U.S. FDA, covering the entire washing–pelletizing–solid-state polymerization (SSP) process (C–G application conditions). This milestone made Polytech the first company in Asia to obtain FDA NOL approval for a complete PET bottle-to-bottle food-grade recycling process and turnkey equipment solution.

More recently, Polytech received an additional standalone FDA NOL certification for its SSP technology, enabling further improvements in intrinsic viscosity (IV) levels and reductions in acetaldehyde content—fully meeting the stringent standards of bottle-to-bottle recycling.

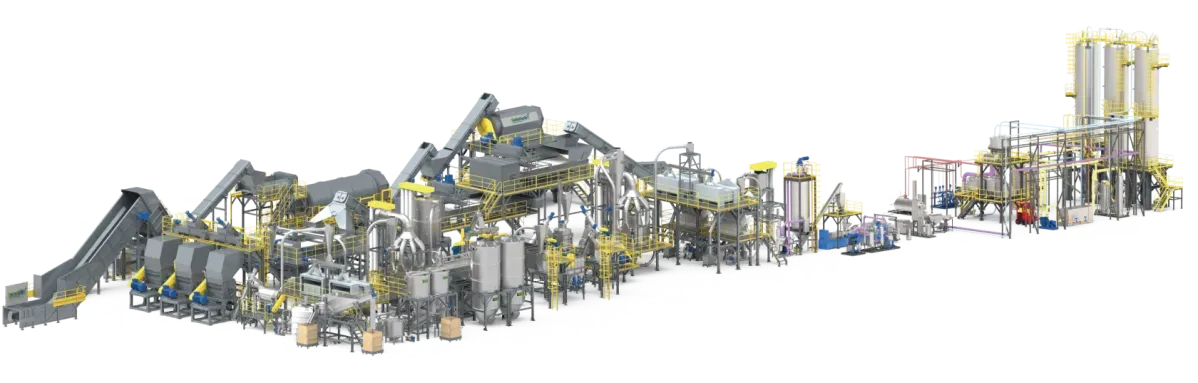

Integrated Engineering Solution: From PET bottle collection, sorting, and washing to melt pelletizing and SSP, Polytech provides a complete food-grade rPET production line, ensuring every step complies with food-contact safety standards.

Polytech has successfully deployed bottle-to-bottle food-grade recycling lines in multiple countries, gaining extensive expertise in quality control and process optimization, allowing seamless adaptation to China’s evolving regulatory framework.

Today, the technical conditions for industry development are becoming increasingly mature, and market demand continues to build. For Polytech, this represents not only a new growth opportunity but also a stage to showcase its world-leading bottle-to-bottle recycling technology. In the future, when a discarded beverage bottle goes through washing, pelletizing, and other processes at a recycling plant to be reborn as a food-grade bottle, it may very well have been produced on a line designed and built by Polytech.