From a Struggling Small Factory to a Recycling Giant with NT$5.4 Billion in Revenue: How PolyGreen Used R&D to Win Over Costco and Meiji

Source:Manager Today

DateTime:2025-11-10

Written by

Yu-Ju Wang

A bulk carrier loaded with recycled PET flakes was approaching the coast of Wenzhou, China, when it was suddenly intercepted by customs. The shipping documents declared only 30 or 40 tons — but in reality, it carried 400 tons. It was nearly confiscated as contraband.

BoReTech Resource Recycling Engineering Chairman Ou Xiwen recalls that day vividly. In 1994, upon hearing the news, he took an 18-hour overnight bus to the port and paid RMB 300,000 to “redeem” the shipment. That cargo was crucial to his fledgling chemical fiber venture in China — and saved it from collapse before it even began.

Back in 1991, Ou’s father ran a shoe material business in Taiwan. To support the government’s recycling initiative, he built a factory for washing and recycling PET bottles. But environmental awareness was low, and no one wanted to use recycled materials in textiles or consumer products. The factory soon filled with thousands of tons of unsold PET flakes.

That abandoned stock became Ou Xiwen’s ticket to China. He processed the PET flakes — made from cleaned and shredded bottles — into short synthetic fibers for China’s booming textile market. That move marked BoReTech’s first step into the recycled fiber industry.

The early days were brutal. The technical team quit just before production began, equipment suppliers delayed deliveries and inflated prices, and even business partners underreported cargo weights to pocket the difference — forcing Ou to rush to customs personally to save his shipment.

Thirty Years Later: From Unsold Stock to a Vertically Integrated Recycling Empire

Three decades later, BoReTech has evolved from a small, unsellable-fiber factory into a vertically integrated recycling group spanning production line design, engineering, PET bottle washing, pelletizing, and fiber spinning. In 2024, its annual revenue surpassed NT$5.4 billion, and the company is set to go public in March 2025.

In-House R&D: Selling Equipment to 40 Countries, Driving 40% of Revenue

“In those days, our biggest advantage was management discipline,” says Ou Xiwen. After gradually assembling a technical team in China, BoReTech began producing short polyester fibers used as filling in jackets, down coats, and car interiors — all in high demand at the time. Sales took off immediately, and monthly output rose from 250 tons to 730 tons.

By 2001, BoReTech’s annual fiber output reached 35,000 tons, and Taiwan’s PET supply could no longer meet demand. The company began sourcing recycled materials worldwide. However, without global recycling standards, material quality varied widely. To stabilize fiber quality, Ou decided to move upstream — leveraging his expertise to design PET washing systems and sell them to suppliers, helping them produce higher-grade PET flakes.

In 2003, BoReTech established its Resource Recycling Equipment Division, starting small but eventually growing into Zhejiang BoReTech Co., specializing in PET bottle recycling and washing equipment.

“At first, customer complaints were endless,” recalls Paul Ou, current Chairman of BoReTech Taiwan. “Our early machines were like LEGO sets — hard to fit, vibrating constantly, and often needing technicians to cut and weld on-site to keep them running.”

The process was crude but effective. BoReTech’s 30-member engineering team supported each client through testing and system setup. For instance, PET bottles use different label types — adhesive or full shrink sleeves — each requiring distinct removal methods. BoReTech not only supplied the machinery but also designed customized, efficient process flows that streamlined recycling operations.

The results spoke for themselves. BoReTech’s systems achieved both high quality and low cost, drawing repeat orders worldwide. “Our success comes from selling not just machines, but solutions,” says Paul Ou.

Today, BoReTech’s recycling systems operate in over 40 countries, handling more than 5.8 million tons of PET bottles annually — over 30% of global PET recycling volume. Equipment sales account for 40% of total revenue and around 60% of group net profit.

Six Years to Build a “Bottle-to-Bottle” Revolution — Now Supplying Costco and Meiji

Having grown up in the family business, Paul Ou was deeply influenced by his father’s sustainability ethos. “As a kid, I dreamed of becoming a scientist who invented bugs that could eat garbage,” he laughs. After joining BoReTech, he inherited that drive — spearheading the company’s push into food-grade bottle-to-bottle (B2B) recycling.

Bottle-to-bottle is among the most advanced recycling technologies. Traditionally, used PET bottles were turned into fibers for clothing or upholstery — products that would still be discarded. B2B recycling, however, removes impurities and transforms used bottles back into food-grade PET, allowing them to be made into new beverage containers — achieving a closed-loop cycle.

This requires three key steps — washing, pelletizing, and solid-state polymerization (SSP) — with every stage meeting strict international food safety certifications. BoReTech already had world-class washing systems, but Paul Ou scoured the globe for complementary technologies.

“I found a Czech factory selling a second-hand pelletizing line and flew there immediately,” he says. After acquiring it, he went to the U.S. to secure the full SSP engineering designs and technical licenses. Over six years, BoReTech integrated European systems with its own innovations to complete a full bottle-to-bottle solution, officially launched in 2024.

The effort targeted future market trends. European companies had long dominated the field, charging nearly double Asian prices. “Our strategy was to

surround the cities from the countryside,” Paul explains — entering the market with competitive pricing to build recognition. Today, BoReTech’s B2B systems are used by global clients including

Costco’s Kirkland brand and

Japan’s Meiji Dairy.

A Mission That Became a Business

What began as a chance encounter with recycling has become

Ou Xiwen’s lifelong mission. “Humanity can’t just consume without recycling,” he says. “One day, everything will have to be recycled. This industry lets us make a profit while contributing to the planet — it’s the perfect balance of mission and business.”

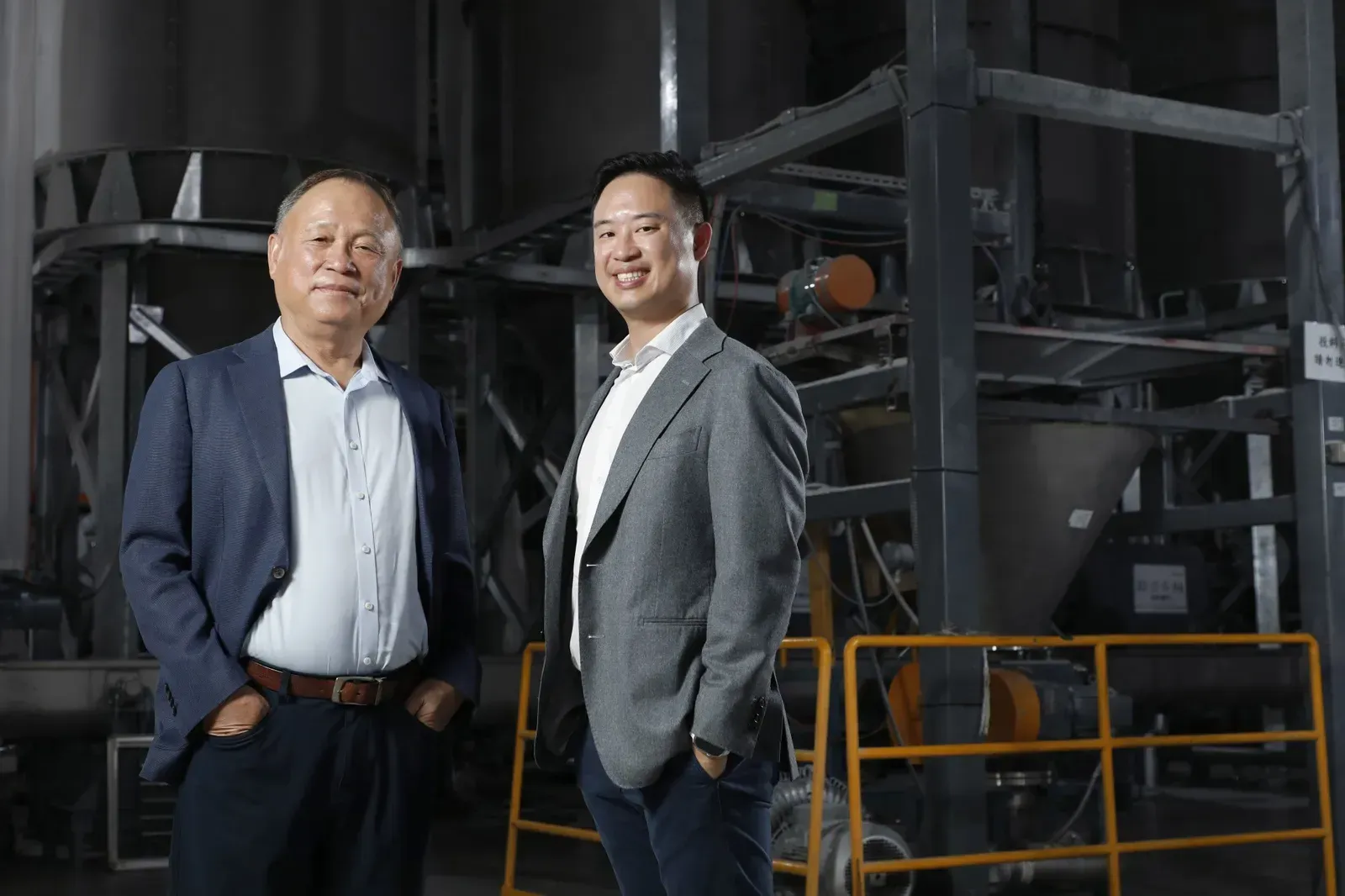

Ou Xiwen

Graduate of Takming College, Department of Business Administration. Founded

Zhejiang Anshun Chemical Fiber in 1994 and led its evolution into a vertically integrated group covering production line design, engineering, PET washing, pelletizing, and fiber spinning. BoReTech is scheduled for public listing in

March 2025.

Paul Ou

B.A. in Business Administration, Meijo University (Japan). Joined BoReTech Group in 2012, overseeing sales; became Chairman of BoReTech Taiwan in 2020. Led development of the

food-grade bottle-to-bottle recycling project.

BoReTech Resource Recycling Engineering Co., Ltd.

Founded: 1994

Employees: 727

Revenue: NT$5.44 billion in 2024; NT$2.45 billion in the first half of 2025 (+6.5% YoY)

Operations: Resource recycling — vertically integrated across production line design, PET washing, pelletizing, and fiber spinning.